Email

Emailsales@rondgebelting.com

conveyor@vip.163.com

Base belt

Sidewall conveyor belts require a certain tensile strength and abrasion resistant ability . For belt with lateral free space , the belt has to have enough cross rigidity transversely and flexibility longitudinally to meet up with the requirement of deflection part of conveyor . We special designed base belt with cross rigidity solved the problem of the belt collapse . The belt width are in accordance with international standard.

Our steel cord breaker is specially designed for sidewall base belt ,which is totally different from the steel mesh that is used for normal flat belt in the market . The internal steel mesh in flat conveyor belt is used for anti-tear , it should have very good troughability ; But the sidewall base belt should have enough cross rigidity transversely and flexibility longitudinally, which means the steel cord breaker we use must have completely opposite performance from the steel mesh used in flat belt .

Sidewall

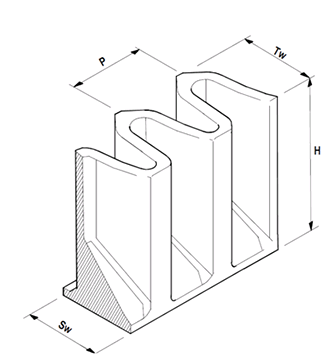

Our corrugated sidewalls represent the latest in design ideas and manufacturing techniques . The sidewall design ensures maximum flexing without fatigue , the profile has excellent vertical stability for load retention and return side support . The design allows for high compression to ensure smooth inner deflection around small radii .Another important design feature is that the sidewalls can be pressed from both sides when mounting , this offers much higher bond strengths and security .

The fabric insertion is the diagonal type which gives excellent tear resistance and also allow the sidewall to flex more easily .

The rubber compounds used have been tested to ensure maximum flexibility along with high abrasion resistant and high strength .

The “in-house”test conveyor designed and built specifically to test the new range of sidewalls has proved the rubber compounds work together in harmony increasing the life of the sidewall and ensuring maximum durability .

Type S standard construction in heights from 40mm to 120mm . Please require if fabric reinforcement is needed for this type .

Type MDSF Heavy duty construction including fabric reinforcement as standard in height from 120mm to 300mm. The fabric reinforcement is of the diagonal type ensuring maximum flexibility with high vertical stability .If required these can be supplied without fabric reinforcement to special order .

Type HHDF Heavy duty special design including fabric reinforcement as standard in heights from 300mm to 630mm .

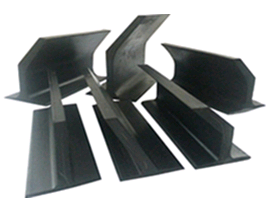

Cleat

We designed special rubber compound for cleats which is with excellent features including impact resistance , correct hardness to avoid cleat deformation under load and high abrasion resistance .

All cleats have been specifically design to give optimum performance . The shape of the “C”and “TC”types has been created to offer best to conveying capacities along with excellent self -cleaning properties .S-wall cleats are either of the extruded type for the smaller profiles , all larger cleats are molded to give the best shape retention even when conveying high -density materials .Cleats are available in 2.45m for molded production length .

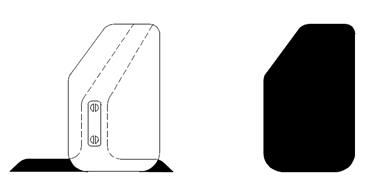

Side Blinkers :

Side Blinkers can be fitted in -between the cross cleats profile and the sidewall to make a seal .Side Blinkers are used when the material is particularly free flowing .

Packing :

Except good raw material , good production equipment and technology etc, the safe and user -friendly packing is also very important for sidewall belting .We have been packing sidewall belt in standard way to ensure the belt is safe during transportation and storage period .

All our belts are supplied in high quality packing to protect them in transit.Belts are transported in a solid metal frame which is either wrapped in seaworthy polyethylene shrink foil or ,on request, placed inside an ISPM 15 treated wooden reels&plates .Protective layers are applied between the sidewalls to avoid intermediate contact .

Sidewall and Cleat

| Name | N | S | ES | ||||||||||

| Type | |||||||||||||

| Sidewall | |||||||||||||

| Height | 40 | 60 | 80 | 100 | 120 | 120 | 160 | 200 | 240 | 300 | 400 | 500 | 630 |

| Structure | |||||||||||||

| Type | TC | TC | TC | ||||||||||

| Height | 35 | 55 | 75 | 90 | 110 | 110 | 140 | 180 | 220 | 280 | |||

| Structure | |||||||||||||

| Type | T | T | TS | TS | |||||||||

| Height | 35 | 55 | 75 | 90 | 110 | 110 | 140 | 180 | 220 | 280 | 360 | 460 | 580 |

| Structure | |||||||||||||

| Type | C | C | TCS | TCS | |||||||||

| Height | 55 | 75 | 90 | 110 | 110 | 180 | 220 | 280 | 360 | 460 | 580 | ||

Non-Standard of sidewall:S136、S220、S270、S360

| Base Belt Width B(mm) | Sidewall Height H(mm) | Cleat height H1(mm) | Bf(mm) | Br(mm) | R(mm) |

| 300 | 40 | 35 | 25 | 180 | 35 |

| 60 | 55 | 50 | 120 | 40 | |

| 80 | 75 | ||||

| 400 | 60 | 55 | 50 | 180 | 60 |

| 80 | 75 | ||||

| 100 | 90 | ||||

| 500 | 80 | 75 | 50 | 250 | 75 |

| 100 | 90 | ||||

| 120 | 110 | ||||

| 650 | 100 | 90 | 50 | 350 | 100 |

| 120 | 110 | ||||

| 160 | 140 | 75 | 300 | ||

| 800 | 120 | 110 | 50 | 460 | 120 |

| 160 | 140 | 75 | 410 | ||

| 200 | 180 | ||||

| 1000 | 160 | 140 | 75 | 550 | 150 |

| 200 | 180 | ||||

| 240 | 220 | ||||

| 1200 | 160 | 140 | 75 | 690 | 180 |

| 200 | 180 | ||||

| 240 | 220 | ||||

| 300 | 280 | 105 | 630 | ||

| 1400 | 200 | 180 | 75 | 830 | 210 |

| 240 | 220 | ||||

| 300 | 280 | 105 | 770 | ||

| 400 | 360 | ||||

| 1600 | 200 | 180 | 75 | 970 | 240 |

| 240 | 220 | ||||

| 300 | 280 | 105 | 910 | ||

| 400 | 360 | ||||

| 1800 | 240 | 220 | 75 | 1110 | 270 |

| 300 | 280 | 105 | 1050 | ||

| 400 | 360 | ||||

| 500 | 460 | 125 | 1010 | ||

| 2000 | 240 | 220 | 75 | 1250 | 300 |

| 300 | 280 | 105 | 1190 | ||

| 400 | 360 | ||||

| 500 | 460 | 125 | 1150 | ||

| 2200 | 300 | 280 | 105 | 1330 | 330 |

| 400 | 360 | ||||

| 500 | 460 | 125 | 1290 | ||

| 630 | 600 | 145 | 1250 | ||

| 2400 | 400 | 360 | 105 | 1470 | 360 |

| 500 | 460 | 125 | 1430 | ||

| 630 | 600 | 145 | 1390 |

Product advantages

1.Quick installation

2.Reduced number of transfer points

3.Long service life

4.Reduced power requirements

5.Quiet running

6.Reduced maintenance

7.Environmentally friendly

Application

Construction industry

Potash and salt mining

Stones and earth

Fertilizer

Chemical industry

Recycling industry

Rural co-ops and traders in agricultural commodities

Agriculture